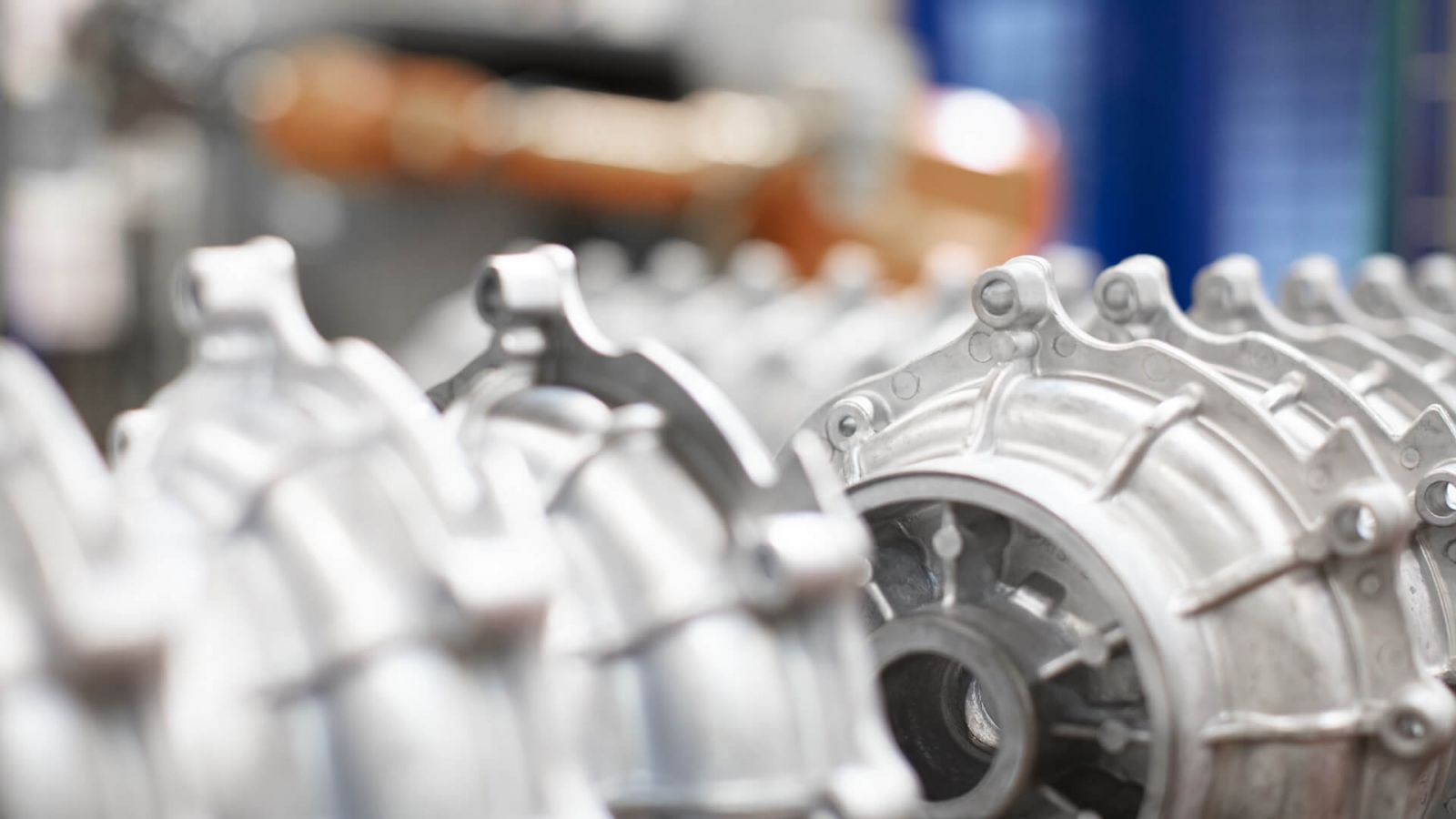

Explore Aluminum Foundry and its role in reliable aluminum casting results

Wiki Article

A Comprehensive Guide to the Manufacturing Techniques Employed in an Aluminum Foundry

The production strategies used in aluminum foundries are diverse and important to the market. Each technique, from sand spreading to additive production, provides distinct benefits tailored to particular production requirements. Recognizing these strategies can significantly influence product quality and efficiency. As the demand for advanced manufacturing remains to grow, the significance of grasping these techniques can not be overstated. What ramifications do these developments hold for the future of aluminum production?Recognizing Light Weight Aluminum Alloys and Their Properties

Aluminum alloys play an essential duty in the production procedure because of their diverse homes and applications. These alloys are mostly categorized into 2 teams: wrought and cast alloys, each with distinctive features. Wrought alloys, such as the 6000 and 7000 collection, are known for their excellent strength-to-weight proportion and rust resistance, making them suitable for structural applications. On the other hand, cast alloys, consisting of the 2000 and 3000 series, show premium fluidness and can be easily built right into complex shapes.

The details buildings of aluminum alloys, such as tensile strength, ductility, and thermal conductivity, are affected by their chemical structure and handling techniques. Elements like copper, silicon, and magnesium are commonly contributed to boost these buildings, tailoring the alloys for details uses in aerospace, auto, and building industries. Recognizing these alloys and their behaviors is vital for optimizing manufacturing procedures and guaranteeing top quality outcomes in aluminum Foundry procedures.

Sand Spreading: A Standard Approach for Aluminum Production

Sand spreading is a widely utilized strategy in light weight aluminum manufacturing that entails producing a mold and mildew from sand to shape the metal. This technique supplies several benefits, such as cost-effectiveness and the ability to create complicated forms, while likewise offering particular disadvantages, including surface area finish limitations and slower production rates. Aluminum Foundry. Understanding both the process and its disadvantages and pros is essential for reviewing its suitability in various applicationsProcess Summary

Among one of the most long-lasting techniques in steel casting, sand casting uses a trusted approach for producing aluminum components. This process begins with creating a mold and mildew from a blend of sand and a binding representative, which is formed to match the wanted component. As soon as the mold and mildew is prepared, molten light weight aluminum is put right into the dental caries, permitting it to take and fill the space on the mold's form. After cooling down, the mold and mildew is damaged away to expose the actors aluminum component. Any type of needed finishing processes, such as machining or surface area therapy, can then be related to attain the last specs. Sand casting is widely utilized as a result of its flexibility, allowing the production of complex forms and differing sizes efficiently.Advantages and Disadvantages

The sand spreading process offers an one-of-a-kind set of benefits and disadvantages that affect its application in light weight aluminum production. One considerable advantage is its versatility, permitting for the production of intricate sizes and shapes. In addition, sand spreading is economical for low to tool manufacturing quantities, requiring marginal tooling. It additionally has downsides, such as lower dimensional precision and surface area finish compared to more innovative methods. The procedure can be labor-intensive, needing skilled labor for mold and mildew prep work and pouring. Moreover, the manufacturing price may be slower, restricting its effectiveness for high-volume applications. On the whole, while sand casting stays a sensible choice for several aluminum elements, its constraints need to be taken into consideration in the context of specific production needs.Die Spreading: Accuracy and Performance in Production

Die casting stands as a keystone of aluminum Foundry manufacturing, providing unequaled precision and effectiveness. This technique entails compeling molten aluminum right into a steel mold and mildew under high stress, resulting in regular and very exact elements. The procedure permits for intricate designs and tight resistances, making it optimal for applications in automotive, aerospace, and durable goods.The effectiveness of die casting appears in its fast production rates, which significantly reduce lead times. Additionally, the approach decreases waste, as excess metal can be reused. The toughness of die-cast parts improves the long life of items, lowering the demand for regular substitutes.

Die spreading supports different surface coatings and additional procedures, including to its adaptability. This combination of accuracy, rate, and product conservation placements die casting as a preferred choice for manufacturers looking for affordable remedies without giving up top quality. In the competitive landscape of light weight aluminum Foundry practices, die spreading stays an important strategy.

Investment Casting: Getting Complex Geometries

Although usually eclipsed by die casting, financial investment spreading plays a considerable function in aluminum Foundry production by making it possible for the development of parts with fine information and detailed geometries. This method entails creating a wax pattern, which is coated in a ceramic shell. Once the shell solidifies, the wax is disappeared, leaving a dental caries that reflects the desired shape of the end product.Financial investment spreading is particularly beneficial for creating complicated components that might be impossible or challenging to attain via various other techniques. The procedure permits high dimensional accuracy and a smooth surface coating, reducing the need for comprehensive machining. Furthermore, it supports a broad variety of alloys, improving its convenience in manufacturing applications. By making use of financial investment spreading, shops can fulfill the demands of markets such as aerospace, vehicle, and clinical, where precision and intricacy are vital.

The Function of Additive Manufacturing in Aluminum Foundries

Additive production is significantly acknowledged for its transformative capacity in aluminum foundries, providing benefits such as reduced material waste and boosted layout adaptability. Numerous strategies, including 3D printing and binder jetting, are being adopted to improve production procedures and enhance efficiency. As the industry evolves, future fads may even more integrate additive production, reshaping traditional Foundry techniques.Advantages of Additive Manufacturing

As the manufacturing landscape evolves, the assimilation of additive manufacturing in aluminum foundries offers a transformative change in production capabilities. This ingenious technique provides numerous considerable benefits, consisting of minimized material waste, as it enables accurate layering and marginal extra. Additionally, additive production promotes rapid prototyping, allowing quicker models and adjustments during the style stage. This technology likewise supports the development of intricate geometries that traditional approaches may struggle to attain, boosting product performance and efficiency. It can simplify supply chains by allowing localized production, reducing transportation expenses and lead times. Eventually, the adoption of additive production encourages aluminum factories to enhance effectiveness, enhance product high quality, and fulfill the expanding need for personalization in manufacturing.

Usual Strategies Used

Discovering the landscape of aluminum shops discloses a variety of usual methods that take advantage of additive production to improve production procedures. One common method is using 3D printing for producing complex molds, which enables detailed layouts that conventional techniques can not achieve. This strategy lowers product waste and reduces preparations substantially. Furthermore, binder jetting is used to produce sand mold and mildews directly from digital models, streamlining the fabrication process. One more method involves the integration of metal additive manufacturing, which allows the manufacturing of extremely customized light weight aluminum parts. These methods not just improve efficiency yet additionally contribute to innovation in style, permitting shops to satisfy varied client needs while preserving premium criteria.

Future Trends in Market

While the aluminum Foundry market has traditionally depended on standard production methods, the combination of additive manufacturing is poised to redefine manufacturing paradigms. This ingenious method enables for the creation of intricate geometries that are usually difficult to achieve through typical casting techniques. By enabling rapid prototyping and lowering product waste, additive manufacturing improves efficiency and sustainability within light weight aluminum shops. Furthermore, this modern technology helps with personalization, permitting makers to fulfill specific client needs without extensive retooling. As the market accepts digitalization, improvements in 3D printing innovations will likely result in quicker production cycles and minimized preparations. As a result, the future of aluminum foundries is increasingly intertwined with the capacities and advantages offered by additive manufacturing.High Quality Control Steps in Aluminum Foundries

Quality control procedures in aluminum shops are fundamental to ensure the integrity and efficiency of actors items. These actions consist of rigorous inspection processes, which encompass both aesthetic evaluations and advanced testing techniques such as X-ray radiography and ultrasonic screening. Keeping an eye on vital specifications, such as temperature and alloy composition throughout the melting and pouring processes, is essential to ensure the preferred product residential properties.Furthermore, adherence to standardized procedures, such as ISO qualifications, helps keep consistent top quality. Statistical process control (copyright) methods are frequently used to assess manufacturing information, permitting the identification of trends and prospective issues early in the manufacturing cycle.

Future Trends and Developments in Aluminum Spreading Techniques

As the aluminum casting industry advances, ingenious techniques are arising to improve effectiveness and product top quality. One significant pattern is the integration of innovative automation and robotics, which improve procedures and lower labor costs. This change permits constant accuracy in spreading, decreasing problems and improving general output.Furthermore, the adoption of 3D printing technology for pattern-making is getting grip, allowing fast prototyping and the production of complex geometries that typical techniques struggle to attain. Furthermore, using simulation software assists in more precise forecasts of product behavior during spreading, bring about optimized designs and lowered waste.

Sustainability is likewise a focal point, with efforts toward recycling aluminum scrap and embracing green practices in foundries. These developments reflect a commitment to advancing aluminum casting strategies, ensuring enhanced performance, lowered ecological impact, and flexibility to market needs. The future of light weight aluminum spreading guarantees significant improvements that will certainly reshape the sector landscape.

Regularly Asked Questions

What Precaution Are Implemented in Aluminum Foundries?

Safety actions in light weight aluminum foundries include individual safety devices, air flow systems, normal security training, emergency methods, and checking for unsafe products (Aluminum Foundry). These methods intend to minimize risks related to high temperature levels and prospective chemical exposureExactly How Is Waste Managed in Aluminum Spreading Processes?

Waste management in light weight aluminum spreading procedures generally involves reusing scrap steel, using correct containment for hazardous products, and using efficient purification systems. These practices decrease environmental influence and advertise resource sustainability throughout the manufacturing cycle.What Ecological Laws Impact Light Weight Aluminum Foundries?

Environmental guidelines considerably influence aluminum factories by enforcing standards on discharges, garbage disposal, and energy intake. Conformity guarantees sustainable techniques, reduces ecological impacts, and advertises the responsible use resources throughout the light weight aluminum production process.Just How Do Foundries Manage Tools Maintenance and Services?

Factories commonly implement arranged upkeep programs, conducting routine maintenances to assure equipment operates effectively. They may use specific professionals and utilize predictive maintenance modern technologies to minimize downtime and enhance overall operational efficiency.What Are the Common Lead Times for Aluminum Casting Projects?

Normal preparation for light weight aluminum spreading tasks can differ substantially, typically varying from a Aluminum Foundry couple of weeks to a number of months. Aspects influencing these timelines include job complexity, material schedule, and the Foundry's current workload and ability.Sand spreading is an extensively made use of method in aluminum production that includes producing a mold from sand to shape the steel. One of the most enduring methods in steel casting, sand casting provides a trusted approach for creating aluminum parts. The sand spreading process presents an one-of-a-kind set of advantages and disadvantages that affect its application in aluminum production. Often overshadowed by die spreading, investment spreading plays a considerable role in light weight aluminum Foundry manufacturing by making it possible for the development of components with detailed geometries and fine details. Waste management in light weight aluminum casting procedures usually involves recycling scrap steel, using correct containment for unsafe materials, and using reliable filtering systems.

Report this wiki page